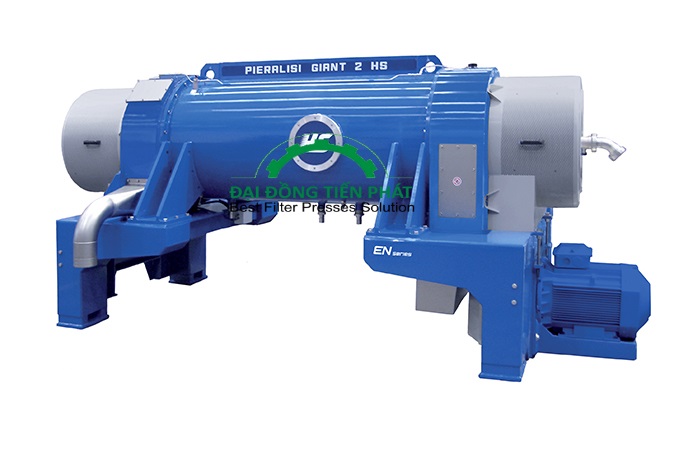

Decanter centrifuge

Decanter centrifughe a high-tech product, being applied for separation of water and liquid from wasted sludge. In order to get the solid out, a screw is desingned inside the centrifuge bowl of sludge dewatering centrifuge.

DECANTER CENTRIFUGE

Dotapha makes better environment for the future, considers human beings and environment as the most valuable, and supplies excellent technology-based environment-friendly and industry-friendly products.

Screw decanter centrifuges designed to separate a wide range of materials for industrial works are used to purify, dewater, concentrate, separate and wash fine solid materials included in various cloudy liquid. We provide a variety of useful centrifuges for hard applications which can never be dealt with in traditional ways.

DDTP type’s structure diagram

- Gear box

- Bowl

- Screw conveyor

- Casing

- Bearing block

- Automatic device

- Anti-vibrator

- Liquid outlet

- Solid outlet

- Fame

- Driving device

Screw decanter centrifuge’s application process

- Concentration: To control the concentration of solid materials

- Separation: To separate solid materials according to their particles

- Purification: To remove solid from liquid materials

- Dewatering: To dewater solid materials

- Washing: To eliminate impurities from the inside of solid materials to better purify

Screw decanter centrifuge’s principle

The screw decanter centrifuge is composed of a bowl, screw conveyor, gear box driving part-protecting casing, driving device which rotates the bowl, differential gear which adjusts the revolution of the screw conveyor, and electric control panel. The bowl rotates at high speed. And the revolution number of the screw conveyor within the bowl can be set operated or adjusted by the differential gear.

Screw decanter centrifuge’s structural function

The function ò the screw centrifuge is to provide centrifuge force for the slurry entered into the bowl, to quickly settle the solid using the difference in specific gravity between liquid and solid, for the rotating crew conveyor to convey the settled solid to the solid outlet, and to dewater the solid at conical slope where they are discharged. Then, the supernatant is discharged to the separated liquid outlet through the spiral path.

Screw decanter centrifuge’s features

- Applicable for a wide range of physical properties

- Larger capacity & faster performance

- Fully automatic running without operator

- A variety ò models are available on request

- The rotating body and liquid-contacted parts are made of stainless steel, and the parts exposed to high abrasion are made of special alloy, so that they can have excellent durability and high anti-abrasion

DDTP MODELS OF SCREW DECANTER CENTRIFUGE

The models have the capacity to treat particles having a size of 1 µm – 10mm and high concentration of 0.1% ~ 50%.

Features

This is used to rapidly treat a wide range of solid particles, without using any screen, filtering colt and washing water. Even in a smaller apace. In addition, it features higher solid recovery, less solid moisture and higher reaction to solid concentration.

Applications

- Environment: pre-treatment of food, human excrements and cattle excrements

- Food: Ethanol, juice and starch

- Chemical: synthetic resin, fertilizer, inorganic chemical and soda

- Industrial waste water: Collected water, painting dyeing, plating, paper manufacturing, power station, and steel mills

- Oil: waste oil, lubricant, cutting oil and fish oil

- Civil engineering: Mining and excavation

Standard specifications

|

Model |

Treating capacity (m3/hr) |

Main power motor |

Centrifugal force |

Weight |

Dimension (mm)

|

||

|

A(Depth) |

B(Width) |

C(height) |

|||||

|

DDTP-100 |

0.2~1 |

3.7 |

2000~3000 |

450 |

1700 |

520 |

1000 |

|

DDTP-200 |

1~5 |

5.5~7.5 |

2000~3000 |

700 |

2000 |

650 |

1200 |

|

DDTP-300 |

5~10 |

11~15 |

2000~3000 |

1500 |

2800 |

820 |

1440 |

|

DDTP-400 |

10~20 |

15~30 |

2000~3000 |

2500 |

3100 |

910 |

1690 |

|

DDTP-500 |

20~30 |

30~55 |

2000~3000 |

3500 |

3500 |

1100 |

1890 |

|

DDTP-600 |

30~50 |

55~75 |

2000~3000 |

4000 |

4100 |

1200 |

1950 |

|

DDTP-700 |

50~70 |

75~105 |

2000~3000 |

5000 |

4500 |

1400 |

2100 |

(Note): 1. The above treating capacity, main power motor and centrifugal force vary depending on slurry type, solid concentration, particle size, recovery and solid moisture. Also, the electric rate, special material, initial tile and differential gear are optional.

2. The above specifications are subject to change without prior notice for the quality enhancement.