Filter press

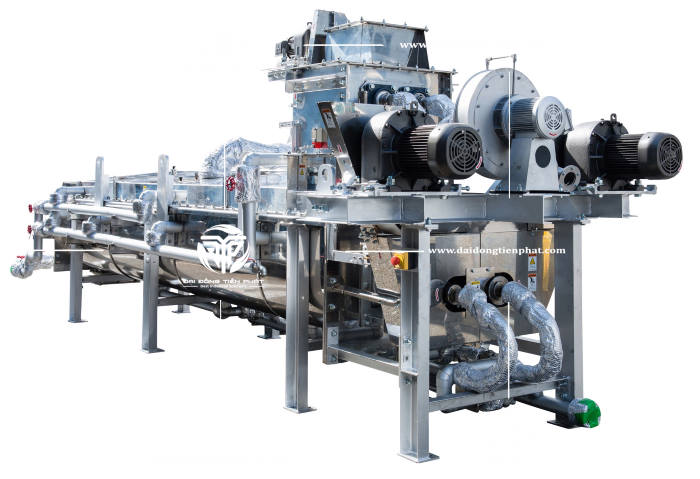

Industrial Filter Presses have been the focus of Manufacturing for many years. Filter presses (also known as Plate and Frame) have many benefits. One, in particular, is that for such a large piece of machinery it has few parts to it.

Being born in 1800, the plate and frame filter press is an effective solution in wasted sludge treatment, which helps to separate water from sludge in order to reduce the volume of wasted sludge to the lowest level with the dryness of solid sludge being up to 40%.

This is an item necessary for the wastewater treatment system of the factory and enterprise, which helps saving the operation costs such as chemicals, electricity and water. At the same time, reducing of the cost for collecting and treating of wasted sludge, contributing to protection of environment and avoiding pollution to surrounding environment.

Plate filter press has a simple structure, consisting of many filter plates being covered by a filter cloth. Depending on its capacity, the number of filter plates is changed. Filter plates are tightly clamped to form many filter chambers containing of sludge residue. Sludge is pumped from the sedimentation tank into its filter chambers by high-pressure pump (diaphragm pump or screw pump).

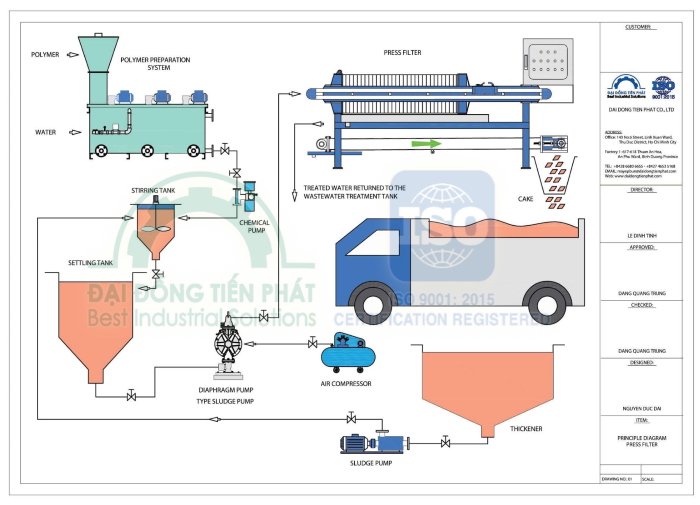

I. WORKING PRINCIPLE - FILTER PRESS

During the process of feeding slurry into the filter press, the separation process is taken place on the surface of filter cloth in the chamber due to pressing pressure from hydraulic cylinder system. Solid slurry particles are retained on the surface of filter cloth and filtrate pass through and drain away through the pipeline.

When sludge residue has been accumulated and filled up the filter chambers, the slurry pump is disconnected. Plate frames are separated out manually or automatically to discharge mud cakes. The discharged mud cake is collected by belt conveyor system to a collection place of mud as specified.

II. MEMBRANE FILTER PRESS

- What is a Membrane Filter Press?

- When you want the frame filter press to solve the following problems

- When maximum phase separation is required

- When high filtrate purity is required When minimum filter cake humidity is required

- When cost-effective cake washing is required

- When high excess pressure is required to separate a slurry. At that time, you might want to consider the mebrane filter press

The initial operation of a membrane filter press is identical to that of its recessed chamber counterpart. However, once the filtration cycle is complete and final filtration pressure is achieved and the feed into the filter press is stopped. At this point the plates within the Filter Press can be inflated using either air or hydraulic pressure to exert a mechanical force on the filter cake retained in the chamber. Pump pressure is 6 ~ 15 bar. The effect of the squeeze is to physically compress the filter cake and force out additional moisture held within the cake giving a drier end result. Since then, helping to clean the filter cloth more easily, reducing the cost collection and subsequent sludge treatment, ensuring hygiene in the transport of sludge.

1. Fiiling: Sludge liquid enters the chambers through a feed pump in the upper right corner. Sludge liquid will fill each chamber sequentially.

2. Filtration: Once the chambers are full, the mash that is being pushed by the feed pump will force the liquid out from the chambers.

3. Compression: Once the Feed Pressure has cycled out, the system will be closed and the membrane squeeze will begin.

4. Draining: As the Squeezing is happening, the liquid will be forced out of the chambers and and exit through the pipes along the filter cavity

5. Grain Discharge: The hydraulic closure of press is opened. Each chamber is opened up for cleaning and grain discharge.

III. APPLICATION OF PLATE FILTER PRESS

-

Dewatering sludge industrial water treatment

-

Kaolin, ceramics, ceramic tiles, sand, ore and minerals

-

Chemical, oil and gas Industry of food production

-

Refining of oil, rice flour, fishing sauce, coffee, soy bean and fruits

Dai Dong Tien Phat Co.,ltd is the first pioneer in manufacturing of plate filter press in Vietnam in 2007. With more than 13 years of experience in researching, manufacturing and installation, our production capacity is more than 20 pcs/ per month with different size ranges, from size of 500 x 500 to 2000 x 2000mm, with semi-automatic or fully automatic model. We have experience in installing and handling of almost all types of sludge from many different specific industries.

For each different industry, the property of sludge and treatment method is completely different. Thus, the working experience, together with the accurate calculation method of capacity becomes perfect connecting pieces for the plate and frame filter press manufactured and fully installed by our company.

With those strengths and capabilities, in 2017, Dai Dong Tien Phat was issued with a Certificate of Quality management of ISO 9001: 2015 by BOA-IAF International Certification Organization. This is also a competitive advantage of filter press made by Dai Dong Tien Phat Co., ltd in Vietnam and international markets.

|

CÔNG TY TNHH ĐẠI ĐỒNG TIẾN PHÁT Hotline: 0274 6535 168 Email: [email protected] Website 1: www.fuegia.com Website 2: Website 3: Văn phòng Miền Nam: 617 -618 Đường Thuận An Hòa, An Phú, Thuận An, Bình Dương Văn phòng Miền Bắc: Số 39, Ngõ 100/27 Phố Sài Đồng, P. Sài Đồng, Q. Long Biên, TP. Hà Nội |